[Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract

The official website of Shanghai Songjiang Group will introduce to you: [Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow contract information, Songjiang Group has provided DN100 stainless steel flange ANSI Flanged Rubber Bellows for many hydropower stations. Following are detailed introduction.

![[Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract [Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract](https://www.ansi-rubber-bellow.com/wp-content/uploads/2022/06/Guizhou-Tianshengqiao-Hydropower-Station-Project.jpg)

Introduction of Tianshengqiao Hydropower Station Project:

The Tianshengqiao Hydropower Station is located on the Leigongtan section of the Nanpan River at the junction of Yuanxiangbo Township and Yahu Township in Longlin County, Guangxi Province, and Dewo Town, Anlong County, Guizhou Province. It consists of two-stage hydropower stations that are constructed in stages and continuously constructed. The total installed capacity is 2.52 million kilowatts, and the average annual power generation is 13.445 billion kilowatt hours. Primary power station. The installed capacity is 1.2 million kilowatts and the annual power generation is 5.2 billion kilowatt hours. The second-level power station has an installed capacity of 1.32 million kilowatts and an annual power generation capacity of 5.05 billion kilowatt hours. The first unit generated electricity in 1992.

The Tianshengqiao first-class station is designed with a dam height of 180 meters, a total storage capacity of 10.8 billion cubic meters, an installed capacity of 1.2 million kilowatts, and an average annual power generation of 5.245 billion kilowatt-hours. The dam selection report was completed in December of the same year, the feasibility study report was completed in May 1984, and the preliminary design report was completed in September 1986, which were reviewed and approved by the former Ministry of Water and Electricity. After consulting and evaluating the power station, American Hadza Company, Brazil Consulting Engineers Group, and Engineering Special Consulting Group gave full affirmation and good evaluation to the engineering design. The project was established in 1991, and the diversion tunnel was started in June of the same year. At the end of 1994, the diversion tunnel was closed. At the end of 1997, the gate was closed for water storage. At the end of 1998, the first unit was connected to the grid to generate electricity.

The barrage of the second-level power station is located in the downstream of Tianshengqiao Canyon. The first 220,000-kilowatt unit of Tianshengqiao Hydropower Station was completed in January 1993 to generate electricity. By the end of 2000, all 10 units of the first and second-level power stations had been completed and put into operation. Tianshengqiao Hydropower Station is funded by the state and four parties in Guangdong, Guangxi and Guizhou, and China Southern Electric Power Co., Ltd. is responsible for the construction management on behalf of the owner.

The left bank of the Tianshengqiao Hydropower Station belongs to Anlong County, Guizhou, and the right bank belongs to Longlin County, Guangxi. The upstream is about 90 kilometers away from the Lubuge Hydropower Station on the Huangni River, a tributary of the Nanpan River, and the downstream is 7 kilometers away from the Tianshengqiao II Hydropower Station. The straight-line distance from the power station to Guiyang City in the northeast is 240 kilometers, and it is 250 kilometers away from Kunming City in the west. Tianshengqiao I Hydropower Station is mainly for power generation, with an installed capacity of 1.2 million kilowatts, a guaranteed output of 405,200 kilowatts, and an average annual power generation of 5.226 billion kilowatt hours. After the completion of the power station, the guaranteed output of the downstream Tianshengqiao, Yantan and Dahua hydropower stations will be increased by 888,900 kilowatts, and the annual power generation will be increased by 4.077 billion kilowatt hours. 4,539 hectares of arable land was submerged in the reservoir area, and 44,300 people were migrated. The project officially started in April 1991 and ended on December 25, 1994, and the first unit generated electricity in December 1998.

The catchment area above the dam site is 50,139 square kilometers, the average annual runoff of the dam site is 19.3 billion cubic meters, and the average annual flow rate is 612 cubic meters per second; . The main project is designed according to the once-in-a-millennium flood, the corresponding flow rate is 20,900 cubic meters per second, the reservoir water level is 782.87 meters, and the corresponding discharge volume is 15,282 cubic meters per second; according to the maximum possible flood check, the inflow flow is 28,500 cubic meters per second, and the corresponding reservoir water level 789.86 meters, the corresponding discharge flow is 21750 cubic meters per second. The reservoir is a mountain valley-type reservoir, with a normal storage level of 780 meters and a dead water level of 731 meters. The total storage capacity is 10.257 billion cubic meters, and the effective storage capacity is 5.8 billion cubic meters. It has an incomplete multi-year adjustment capacity. The maximum working head of the power station is 143 meters, the minimum working head is 83 meters, and the design head is 126.65 meters. The dam sits on rock formations composed of limestone, sandstone, mudstone and marl. The basic earthquake intensity in the dam site area is 6 degrees, and the design intensity is 7 degrees.

Introduction to the contract for the use of DN100 stainless steel flange ANSI Flanged Rubber Bellows in the Tianshengqiao Hydropower Station project in Guizhou:

The scanned copy of the contract below is authentic, please do not reprint or modify it. This contract is only used as a proof of supply and not for other purposes. Thank you for your cooperation.

![[Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract [Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract](https://www.ansi-rubber-bellow.com/wp-content/uploads/2022/06/Guizhou-Tianshengqiao-Hydropower-Station-Project-ANSI-Flanged-Rubber-Bellow-Contract.jpg)

[Guizhou Tianshengqiao Hydropower Station Project] DN100 stainless steel flange ANSI Flanged Rubber Bellow Introduction

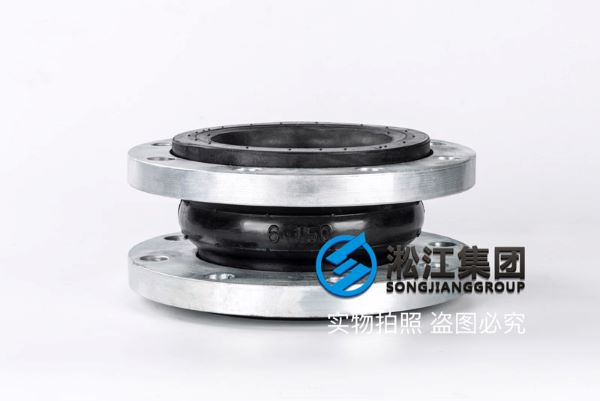

The construction of the hydropower station requires the use of DN100 stainless steel flange ANSI Flanged Rubber Bellows, the flange is made of stainless steel 304, and the rubber is made of steel wire high pressure ANSI Flanged Rubber Bellows.

Songjiang Group ANSI Flanged Rubber Bellows are mainly used in pipelines to reduce vibration, reduce noise, have good flexibility and are easy to use. Single ball ANSI Flanged Rubber Bellows are also known as single ball rubber soft joints, single ball soft joints, shock absorbers, pipeline shock absorbers, shock absorbers It is a kind of pipe joint with high elasticity, high air tightness, medium resistance and weather resistance. This product takes advantage of the elasticity, high air tightness, medium resistance, weather resistance and radiation resistance of rubber. , It is made of high-strength, high-cold-heat-stability polyester cord fabrics that are biased and compounded, and then vulcanized by high-pressure and high-temperature molds. The single-ball ANSI Flanged Rubber Bellow is a fabric-reinforced rubber piece and a flat union. A kind of high elasticity, high air tightness, medium resistance and weather resistance pipe joints.

![[Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract [Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract](https://www.ansi-rubber-bellow.com/wp-content/uploads/2022/06/Guizhou-Tianshengqiao-Hydropower-Station-Project-ANSI-Flanged-Rubber-Bellow.jpg)

The above [Guizhou Tianshengqiao Hydropower Station Project] DN100 stainless steel flange ANSI Flanged Rubber Bellow information comes from the case center of the official website of Shanghai Songjiang Shock Absorber Group Co., Ltd. To Know more Project Cases refer links:

Related Links: Stainless Steel 304 ANSI Flanged Rubber Bellows

![[Guizhou Tianshengqiao Hydropower Station Project] ANSI Flanged Rubber Bellow Contract](https://www.ansi-rubber-bellow.com/wp-content/uploads/2022/06/ANSI-Flanged-Rubber-Bellow-in-Desalination-Project.jpg)