Application case of thread type metal hose in Guangzhou Metro Line 13 Project

The official website of Shanghai Songjiang shock absorber Group Co., Ltd. introduces to you: thread type metal hose in Guangzhou Metro Line 13 Project information. Songjiang Group supplies stainless steel metal hose products for many urban subway projects across the country, which are mainly used in fire protection systems and HVAC systems.

Introduction to Guangzhou Metro Line 13 Project

The Shipai South Station, Phase II of Guangzhou Metro Line 13, is located in the west of Huangpu Avenue, Tianhe District, Guangzhou, with the Pearl River New Town to the south and Huacheng Square, which is the core location of the core area of Guangzhou. The station platform tunnel is buried nearly 40 meters deep, and the stratum is relatively complex. The tunnel passes through fully weathered, strongly weathered, moderately weathered, and slightly weathered rock formations, and the overall excavation is difficult and risky. During the construction of underground tunnels, the surrounding buildings are easily affected by factors such as stratum water loss and soil disturbance. In view of the geological conditions with soft upper and lower hard parts of the tunnel section, the project has continuously strengthened the advanced geological prediction analysis of the surrounding rock of the tunnel.

The construction work surface in Shipai South Station is narrow, the construction temperature in the tunnel is over 38 degrees, and the humidity is high and ventilation is difficult. An axial flow fan is installed in each guide tunnel, which solves the problems of difficult ventilation and high temperature in the tunnel. At the same time, the project department specially purchased an ice maker to transport ice cubes to the tunnel regularly every day to cool down, so as to create a good atmosphere for the operators as much as possible. construction environment.

In order to ensure the smooth pouring of the first slab and the second lining of the whole line, and ensure the high quality of the Year of the Tiger, the project department of Guangzhou Metro Line 13 has held several on-site seminars to optimize resource allocation and strengthen process monitoring. Weekly plan, decompose construction and production tasks into days, and ensure that each node is completed on time. Carry out the safety-themed party class of “Put the Party Flag on the Front Line of Construction and Production”, give case studies to all employees of the project on the front line of construction, use cases to alert front-line employees, convert requirements into action forces, and help promote construction and production safety.

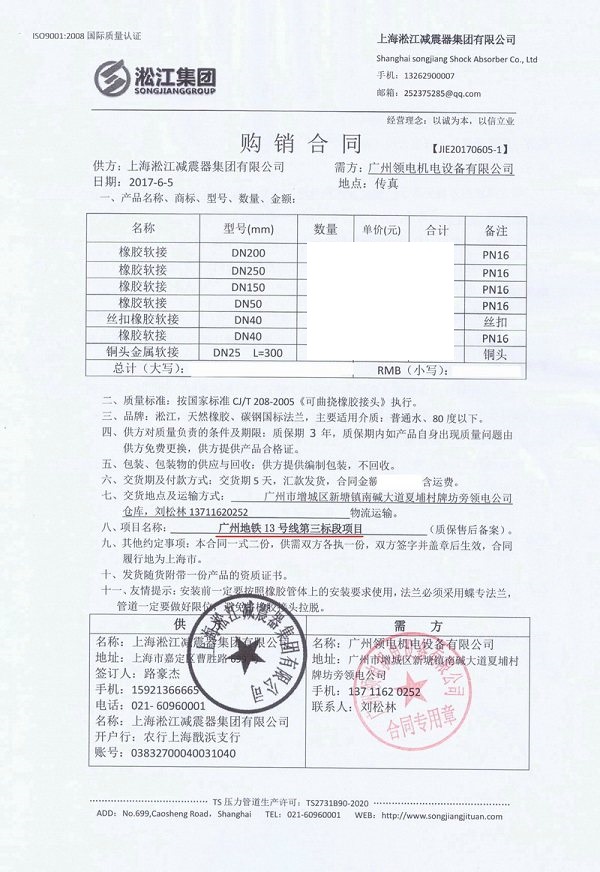

Contract introduction of thread type metal hose in Guangzhou Metro Line 13 Project

Thread type metal hose in Guangzhou Metro Line 13 Project

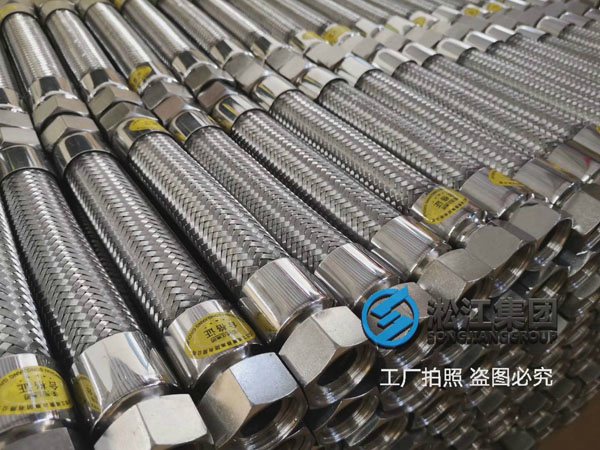

The metal hose is made of austenitic stainless steel because the main parts of the hose are made of austenitic stainless steel, which ensures the excellent temperature resistance and corrosion resistance of the hose. Select the applicable stainless steel * number according to the corrosiveness of the medium through which the pipeline passes, which can ensure the corrosion resistance of the hose.

- The metal hose is made of 1Cr18Ni9Ti stainless steel as a whole, which has strong corrosion resistance.

- The hose body is hydroformed by thin-walled stainless steel body, which has strong flexibility, elasticity, strong bending and anti-vibration ability, and the reinforced protection of the braided mesh sleeve makes it have a higher pressure bearing capacity.

- The connection at both ends of the hose can also be made into other connection methods other than thread and flange standards, which are convenient for connection and use.

- This product is not only suitable for matching with rotary joints, but also widely used in flexible connections for conveying various fluid media. Corrosion resistance, high temperature resistance, low temperature resistance, light weight, small size and good flexibility. Widely used in aviation, aerospace, petroleum, chemical, metallurgy, electric power, paper, wood, textile, construction, medicine, food, tobacco, transportation and other industries.

Related links: Metal Hose