Ansi Rubber Bellows play a crucial role in optimizing operations within automotive factories, offering versatile solutions to various challenges encountered in production processes. Let’s delve into a specific case where the implementation of rubber expansion joints has significantly enhanced efficiency and functionality at shenyang Automotive Manufacturing Plant. Nestled within the expansive grounds of the factory, Songjiang ANSI Rubber Bellows have found versatile applications across various critical systems:

Spray Pipeline Systems: Within the intricate network of spray pipeline systems, ANSI Rubber Bellows have been seamlessly integrated to connect essential components such as paint sprayers and booths. These bellows effectively manage the expansion of pipelines, adapting to temperature fluctuations and vibrations, thus minimizing the risk of paint leaks and ensuring a flawless painting process.

Exhaust Systems: Vital for maintaining air quality and emissions control, the factory’s exhaust systems have been optimized with ANSI Rubber Bellows. These bellows facilitate the connection of exhaust treatment equipment and pipeline networks, effectively managing expansion and vibrations while minimizing the risk of gas leaks and sewage spills, thus ensuring compliance with stringent environmental regulations.

Hydraulic Systems: Precision is paramount in the operation of hydraulic systems, which control the movement of machinery within the factory. ANSI Rubber Bellows have been integrated into hydraulic pipelines, ensuring the seal and stability of the pipes during system operation. By effectively managing expansion and vibrations, these bellows contribute to the smooth functioning of hydraulic equipment, enhancing overall operational efficiency.

Water Supply Systems: The uninterrupted flow of water is essential for equipment operation and employee welfare. ANSI Rubber Bellows have been instrumental in enhancing the factory’s water supply systems, facilitating the connection of pipeline networks. By effectively managing the expansion of water flow and pipeline vibrations, these bellows minimize the risk of water leaks and pipe damage, ensuring a reliable water supply throughout the facility.

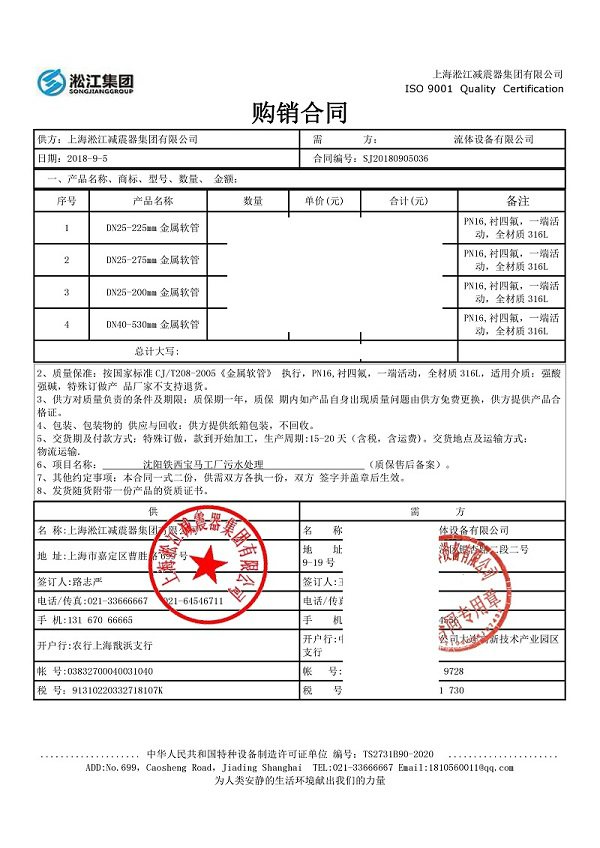

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the implementation of ANSI Rubber Bellows at BMW Tiexi Factory in Shenyang has revolutionized operational efficiency and functionality. By effectively managing expansion, vibrations, and fluid flow within critical systems, these bellows have played a pivotal role in ensuring the smooth operation of the factory, further cementing its reputation as a leader in automotive manufacturing excellence. As the industry continues to evolve, BMW Tiexi Factory remains committed to leveraging innovative solutions to drive efficiency and excellence in its production processes.

Related links:JTW Fully Stainless Steel Metal Hose