In the context of the power plant retrofit project at the Long Gu Tan power plant, a subsidiary of Veolia and the CLP Group, Shanghai Songjiang Shock Absorber Company has provided essential components, particularly the Songjiang ANSI Rubber Bellows. These rubber bellows have demonstrated exceptional qualities that make them the preferred choice for large-scale factory wastewater treatment systems.

Corrosion Resistance: The presence of various chemicals and corrosive substances in the wastewater and sewage of large industrial facilities demands that rubber expansion joints exhibit excellent corrosion resistance. Therefore, the selection of rubber materials like EPDM and Viton is essential to withstand chemical corrosion and the effects of acidic or alkaline substances.

High-Temperature and Low-Temperature Performance: Given the extreme environmental conditions in which wastewater treatment systems may operate, including high or low temperatures, the materials used in rubber bellows need to possess high-temperature and low-temperature resistance. This ensures that the connecting components do not become rigid or brittle in such extreme temperature conditions.

High Strength and Pressure Resistance: Large wastewater treatment systems often involve substantial water flow and pressure. For this reason, rubber bellows must be designed with sufficient strength and pressure resistance to prevent leakage or rupture.

Excellent Flexibility and Bendability: The ability of rubber bellows to withstand flexing and deformation within the system, adapting to pipeline vibrations and changes, is crucial. These bellows must exhibit excellent flexibility to prevent stress concentration and potential ruptures.

Wear Resistance: When dealing with a substantial volume of wastewater, the water may contain particulate matter, leading to wear. Therefore, rubber bellows must be wear-resistant to prolong their lifespan.

Ease of Installation and Maintenance: Large industrial facilities require regular maintenance and servicing of wastewater treatment systems. Consequently, the design of rubber bellows should prioritize easy installation and maintenance to reduce downtime and maintenance costs.

Compliance with Regulations and Standards: Rubber bellows must conform to local and international regulations and standards to ensure safety and reliability. This compliance includes adherence to relevant standards concerning materials, performance, and durability. Wastewater treatment and sewage discharge systems are typically subject to regulatory oversight, making adherence to applicable regulations and standards crucial.

The authentic photo of songjiang rubber expansion joints for Power Plant Retrofit

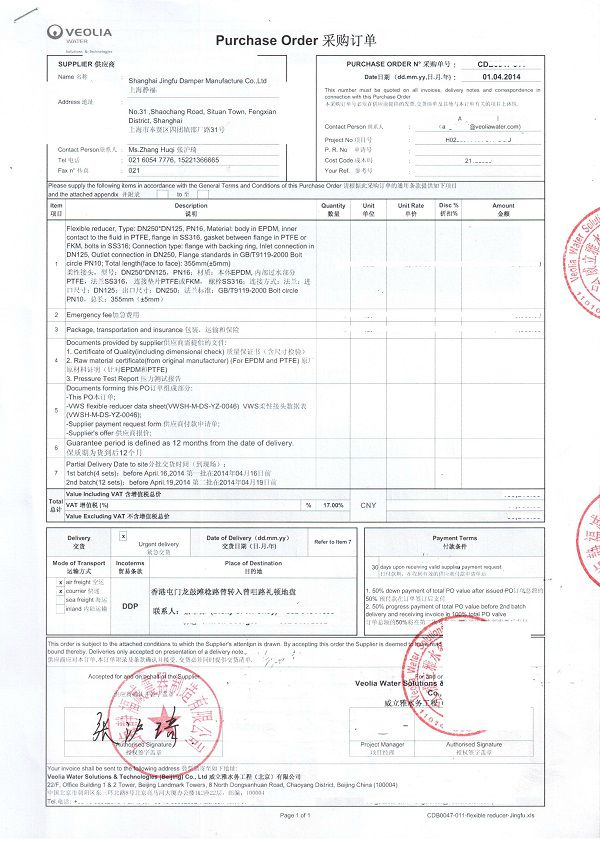

Below is a scanned copy of the authentic agreement. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In summary, Shanghai Songjiang ANSI Rubber Bellows have consistently met these essential requirements, making them an ideal choice for the Long Gu Tan power plant retrofit project. Their outstanding attributes ensure they can effectively operate in the demanding conditions of large-scale wastewater treatment systems.

Related links:[Concentric Reducer] ANSI/ASME Flanged Rubber Bellow