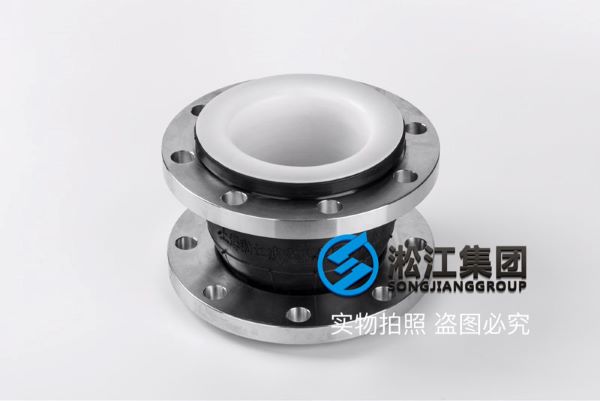

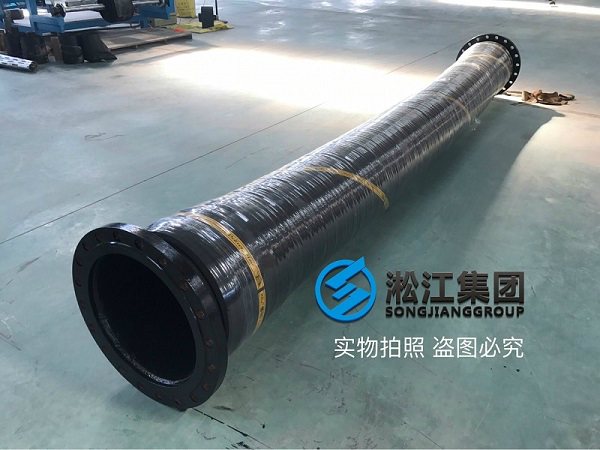

In the dynamic environment of Dongfang Hope Chongqing Cement Plant, maintaining pipeline integrity and operational efficiency is paramount. Songjiang ANSI Rubber Bellows emerge as indispensable assets, offering a multitude of advantages critical for cement plant operations.

Absorbing Pipe Displacement:

In the intricate processes of cement production, pipelines undergo thermal expansion and contraction due to temperature fluctuations. Songjiang ANSI Rubber Bellows effectively absorb these displacements, preventing pipe deformities or ruptures caused by temperature changes.

Vibration Damping:

From mechanical equipment vibrations to fluid surges within the pipeline system, Songjiang ANSI Rubber Bellows efficiently isolate and absorb vibrations, reducing impacts on the pipeline system and minimizing noise levels.

Compensating for Installation Errors:

During pipeline installation, inevitable alignment errors may occur. With their flexibility, Songjiang ANSI Rubber Bellows compensate for these errors, ensuring secure connections and mitigating risks associated with misalignments.

Protecting Pipeline Equipment:

By dispersing stress and preventing stress concentrations, Songjiang ANSI Rubber Bellows safeguard pipelines and equipment, reducing the risk of damage and extending their lifespan.

Enhancing System Stability:

Providing a flexible connection point, Songjiang ANSI Rubber Bellows enhance the overall flexibility and stability of the pipeline system, adapting seamlessly to various operating conditions and environmental changes.

Environmental Adaptability:

In the corrosive environment of cement plants, the corrosion-resistant rubber materials used in Songjiang ANSI Rubber Bellows effectively resist chemical erosion, ensuring long-term durability and reliability.

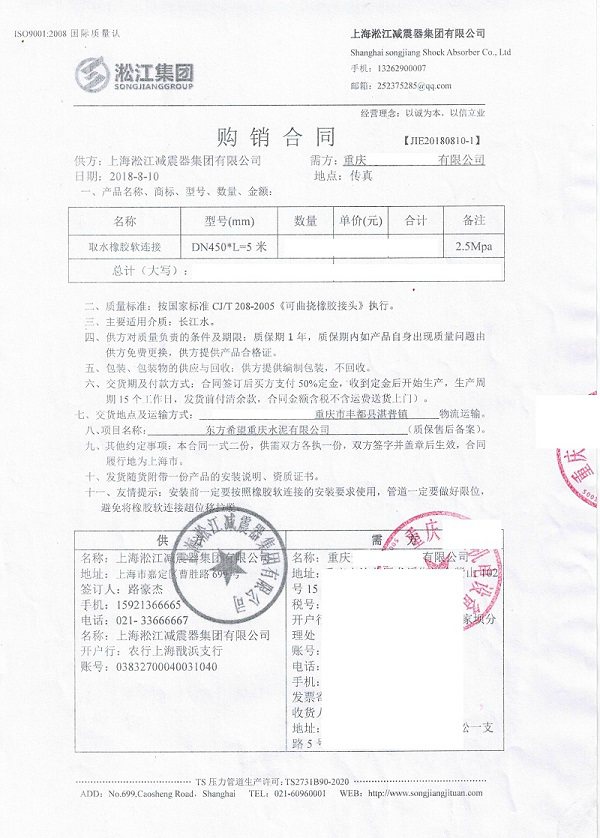

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In summary, Songjiang ANSI Rubber Bellows play a pivotal role in Dongfang Hope Chongqing Cement Plant by absorbing displacement, damping vibrations, compensating for installation errors, protecting pipeline equipment, enhancing system stability, and adapting to complex environments. These functionalities not only improve the reliability and lifespan of the pipeline system but also reduce maintenance costs and operational risks, reinforcing the plant’s commitment to efficiency and sustainability.

Related links:[EPDM] High Temperature ANSI/ASME Flanged Rubber Bellow