The official website of Shanghai Songjiang Shock Absorber Group Co., Ltd. will introduce to you: [China Railway Construction Machinery Research Institute] ansi rubber bellow contract information, Songjiang Group provides oil-resistant ansi rubber bellow products for many engineering projects, mainly for shock absorption and noise reduction , the following is a detailed introduction to the rubber joint contract of China Railway . If you have any need ,you can contact us by the email, sales@songjiangflex.com

1. Introduction of China Railway Engineering Machinery Research Institute:

China Railway Science and Industry Group Co., Ltd. was exclusively initiated by China Railway Group Co., Ltd., a Fortune 500 company, and reorganized and established by three member companies within the group. It is the result of China Railway Group’s integration of internal industrial production resources. The group is a new industrial group integrating scientific research and design, industrial manufacturing, engineering construction and installation, and large-scale logistics. It is located in Wuhan City, the thoroughfare of nine provinces. The company’s business mainly involves railways, highways, bridges, tunnels, subways, buildings, Research and development, manufacture, construction and testing of engineering machinery and steel structures in ports. China Railway Engineering Machinery Research and Design Institute Co., Ltd. (hereinafter referred to as “China Railway Machinery Institute”) is the leading research and development leader of China Railway Construction Equipment and a core member of China Railway Science and Technology Group. National high-tech enterprise and enterprise technology center of Hubei Province, former Ministry of Railways construction machinery standardization technology centralized unit, China Railway Construction Equipment Technology Research and Development Center. The field of equipment research and development involves railways, highways, urban rail transit, tunnels, mines, ocean engineering, ports, etc. The company’s core technology has reached the international advanced level in the fields of research and development of large-scale special construction equipment such as railways and rail transit, construction equipment safety performance testing and remote monitoring and testing technology, and is in a leading position in the industry.

For more than 30 years, China Railway Machinery Institute has vigorously promoted scientific and technological progress, continuously developed new technologies and products, owned more than 60 patented technologies, formulated and revised 23 railway industry standards or national standards, and completed more than 300 scientific research projects. Accumulatively won more than 120 national and provincial science and technology awards, and was approved as “National High-tech Enterprise” and “Hubei Provincial Certified Enterprise Technology Center”. Many large-scale and super-large special construction equipment have been developed for national key projects such as national highways, conventional railways, “eight vertical and eight horizontal” high-speed railway planning and construction, and “One Belt, One Road” construction, making outstanding contributions to national infrastructure construction.

China Railway Machinery Institute is mainly engaged in research and development, production, sales, construction and after-sales of construction machinery products. It has a strong technology development center and a well-equipped manufacturing plant. China Railway Machinery Institute has increased R&D investment year by year, greatly increased R&D of hematopoietic function, and strived to maintain the vitality of innovation and promote the sustainable development of the enterprise. The China Railway Machinery Institute has successfully independently developed the first 50-meter tire belt machine in China, the 2,000-ton double-track gantry crane with the largest domestic lifting capacity, the 4,000-ton steel box girder electro-hydraulic balance module transport vehicle with the largest domestic transport weight, and the domestic The largest 1300-ton offshore bridge erecting machine, 900-ton series box girder lifting, moving, transporting and erecting series equipment, T-beam bridge erecting machine JQ130, JQ170, MDEL180 tire-type beam lifting machine, CCPG500 long rail track laying machine, 850-ton frame Transportation equipment, etc., as well as 190-type railway T-beam inversion, transportation, and erection equipment, battery straight-alternating frequency industrial and mining electric locomotives and electric locomotive marshalling tunnel construction machinery and equipment, as well as a series of powder spraying pile machines, high-frequency hydraulic vibration hammers, resonance crushing Machines, electric shovels and other types of railway, highway, urban rail transit laying machinery and pile workers, tunnels, public works, ports and other mechanical equipment. China Railway Machinery Institute is actively entering the international market. For example, it has produced subway shield machines and other supporting locomotive transportation equipment for Tretec, and exported them to India and Turkey; actively strengthened cooperation with India’s GMR company on the purchase of CCPG500 long rail track laying units; The design of the localization of the double-wheel milling equipment has been completed, and the factory is preparing for manufacturing, etc., and the overseas trade has achieved remarkable results.

China Railway Machinery Institute continues to transform industrial development and scientific and technological achievements into products and industries; takes bridge machinery as the starting point, extends the industrial chain, and becomes a domestic and international leading service manufacturer of bridges and special equipment; pays attention to the new construction of bridges such as railways and highways Technology and new construction methods; improve the profit level of products by means of technological progress; expand the field of special equipment, and occupy the domestic market in open-pit mining, ocean engineering, rail transportation, intelligent informatization, etc.

2. China Railway Research Institute regularly purchases ansi rubber bellow from Shanghai songjiang:

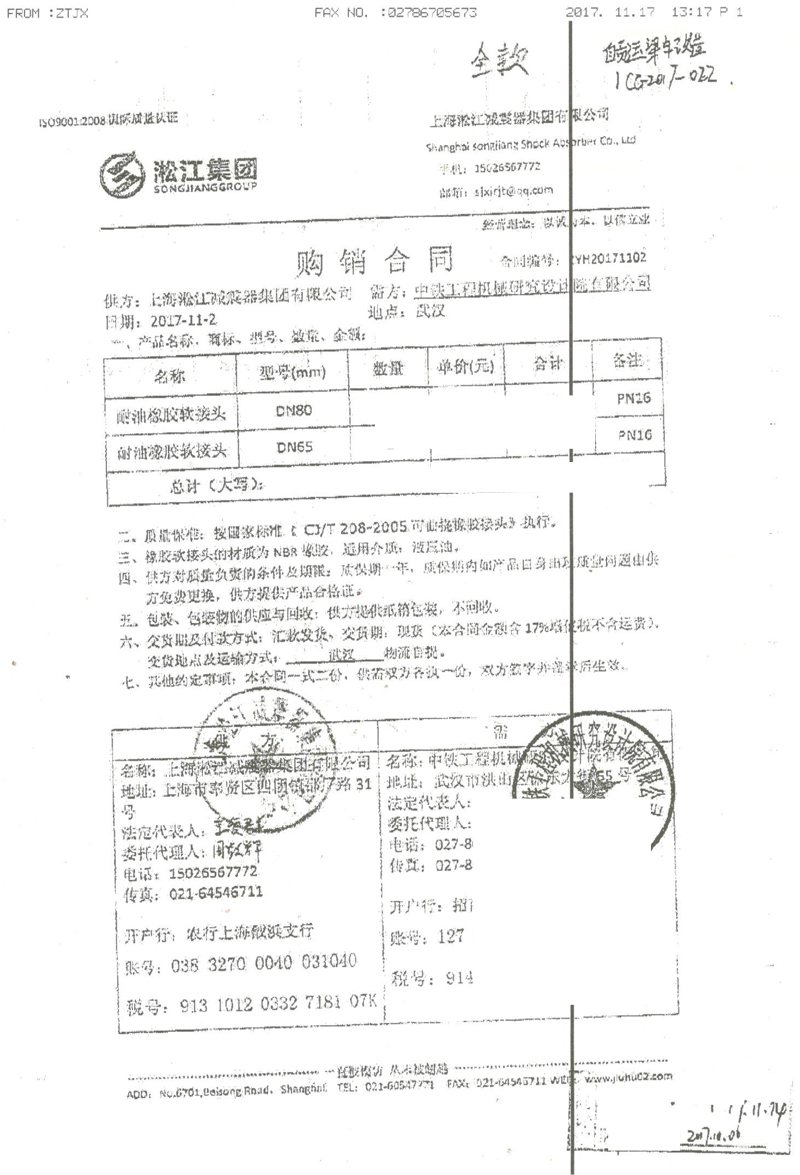

The following is a scanned copy of the authentic contract, please do not modify, please do not reprint, this contract is only used as proof of supply, thank you for your cooperation.

3. China Railway Research Institute regularly purchases ansi rubber bellow from Shanghai songjiang.The following is the introduction of ansi rubber bellow and physical pictures of rubber joints ordered this time:

Good elasticity, good adaptability to compression, stretching, twisting, deflection and vertical displacement, etc., to prevent damage to the piping system caused by thermal expansion and contraction deformation or uneven foundation settlement.

The multi-layer spherical structure is especially suitable for bearing internal pressure, with strong blast resistance, good impact resistance, and no deformation under external pressure.

Cover: Nitrile rubber. The English code of nitrile rubber is NBR. The rubber material is oil-resistant, high-temperature-resistant, and aging-resistant. Strength ≥ 2.0DN/m. Since the outer rubber layer of the rubber joint is exposed to the air, it is easily affected and damaged by external factors, which requires the outer rubber layer of the joint to have properties such as oil resistance, heat resistance, and ozone resistance. For these cases, we use nitrile rubber. Through a reasonable formula, nitrile rubber is mainly suitable for: hydraulic oil and other oil products, and several special oils that cannot be used (aviation kerosene, gasoline, diesel oil). The maximum service temperature of nitrile rubber can reach 140 ℃, and the brittle temperature is -15°C~55°C.

Related Links:[Single Sphere] ANSI/ASME Flanged Rubber Bellow