Shanghai Songjiang Group is excited to highlight the successful deployment of its Ansi Rubber Bellows at the Kaizhou Cement Factory. This partnership demonstrates the effectiveness and reliability of Songjiang’s products in enhancing the operational efficiency and stability of industrial drainage systems.

Project Background

The Kaizhou Cement Factory, located in Kaixian, has been a significant player in the region’s industrial sector. Given the demanding nature of cement production, the factory required a robust and flexible solution for its drainage system to cope with thermal expansion, vibrations, and fluid surges. Songjiang’s ANSI rubber bellows emerged as the ideal choice for meeting these challenges.

Key Advantages of Songjiang ANSI Rubber Bellows in the Kaizhou Cement Factory Project:

Superior Flexibility and Adaptability:

The production environment in a cement factory involves frequent temperature changes, leading to expansion and contraction of pipelines. Songjiang’s ANSI rubber bellows are designed to absorb these movements, ensuring the integrity and continuous operation of the pipeline network. This adaptability is crucial in preventing damage and maintaining efficiency.

Effective Vibration Damping:

Machinery and equipment in the cement production process generate significant vibrations. These can compromise the stability of the drainage system. Songjiang’s rubber bellows efficiently isolate and dampen these vibrations, reducing the impact on the pipeline system and minimizing noise pollution within the facility, which contributes to a safer and more pleasant working environment.

Leak Prevention and System Integrity:

Ensuring a leak-free drainage system is vital in industrial settings to avoid costly repairs and downtime. Songjiang’s ANSI rubber bellows provide secure connections that prevent leaks, even under variable pressure conditions. This reliability is essential for maintaining the smooth operation of the factory’s drainage system.

Compensation for Installation Variations:

During the installation of extensive drainage systems, alignment issues can occur. The inherent flexibility of Songjiang’s rubber bellows allows them to compensate for these installation errors, ensuring that the connections remain secure and effective. This flexibility helps in avoiding potential operational disruptions due to misalignments.

Resistance to Corrosive Environments:

Cement production involves exposure to various corrosive substances that can degrade standard pipeline materials. Songjiang’s rubber bellows are made from high-quality, corrosion-resistant materials, ensuring long-term durability and reliability in the harsh environment of a cement factory.

Enhanced Operational Efficiency

The implementation of Songjiang’s ANSI rubber bellows has significantly enhanced the operational efficiency of the Kaizhou Cement Factory. By addressing key challenges such as thermal expansion, vibrations, and potential leaks, these bellows have contributed to the stability and reliability of the factory’s drainage system.

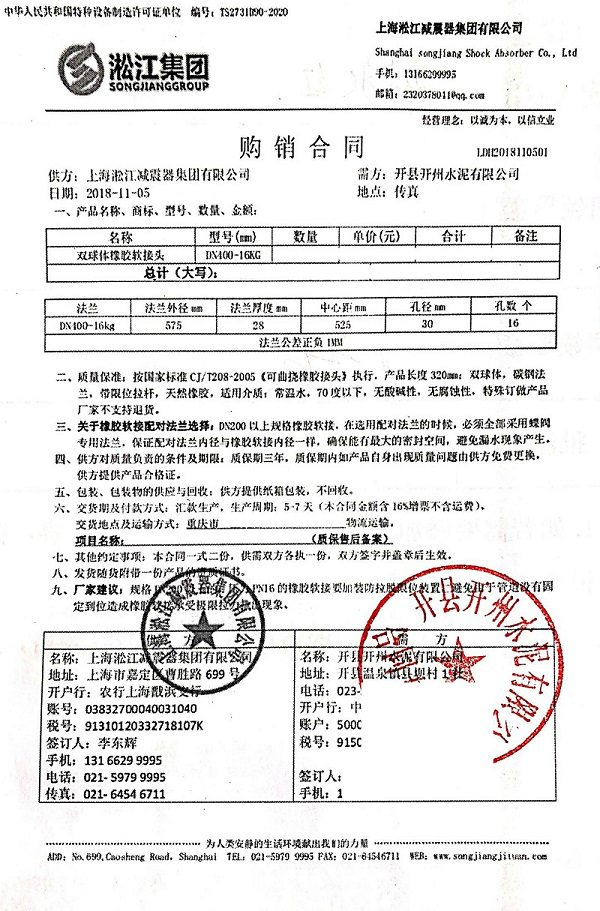

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

The successful integration of Songjiang ANSI rubber bellows at the Kaizhou Cement Factory illustrates their effectiveness in demanding industrial applications. These products have proven to be indispensable in ensuring the smooth operation of the factory’s drainage system. Shanghai Songjiang Group remains committed to providing high-quality, adaptable solutions that meet the diverse needs of industrial clients, reinforcing our position as a leader in the field of pipeline expansion and vibration control.

Related links:[Double Sphere] ANSI/ASME Flanged Rubber Bellow